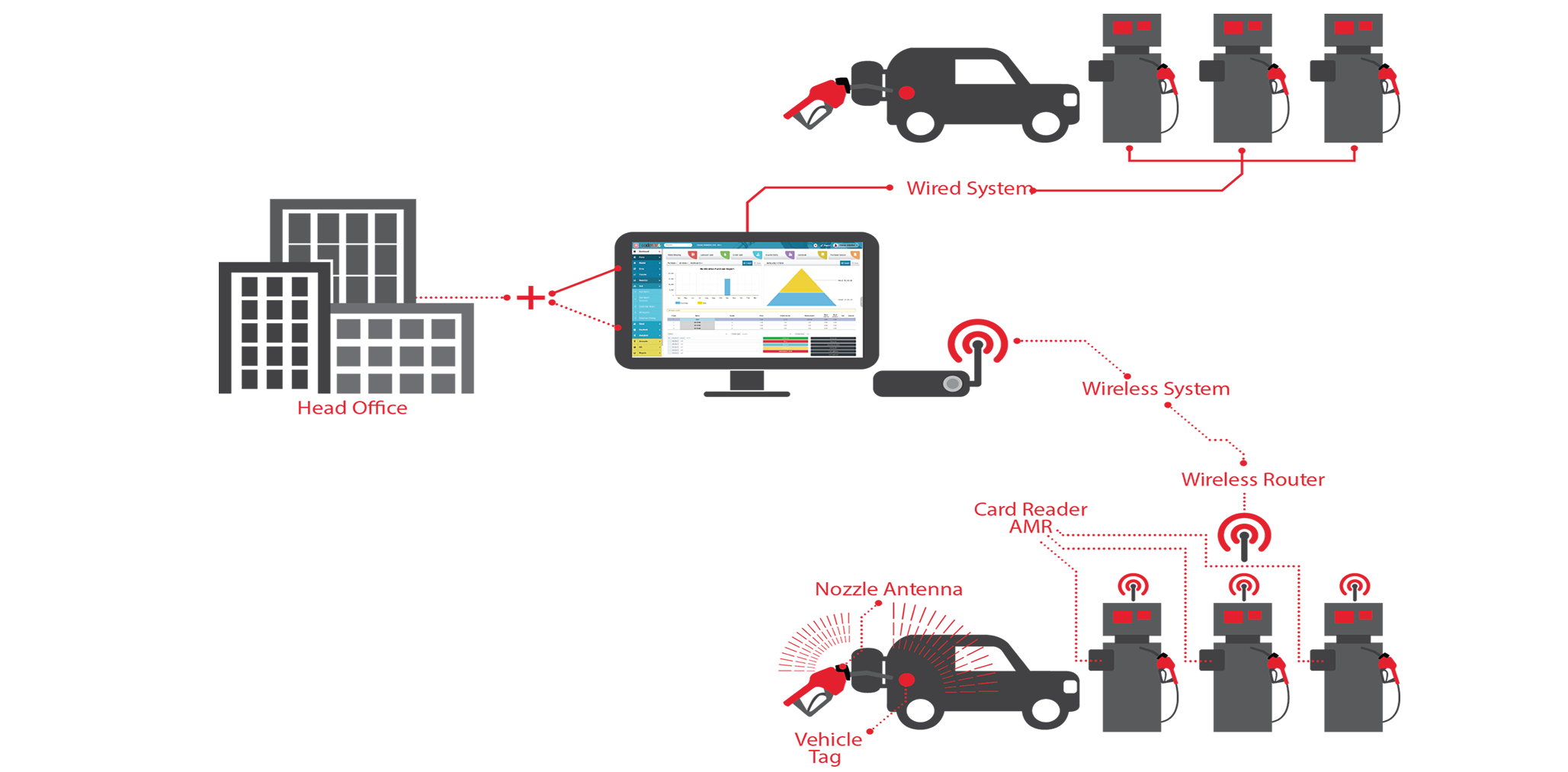

We provide complete pump automation using our unique Forecourt controller allows automation of pumps in a station and control over petroleum, LPG and CNG dispensers and automatic tank gauge systems and probes. It provides control over any of the dispensers on the forecourt and should not matter what are the brands of dispensers and ATG systems its fully integrated to our Cloudbased Petrol Station management System. The complete pump automation simplifies work and allows station owners to have control and receive real time data of sales being done at the station by each pump. The forecourt controller also allows remote access of the dispensers and owners can see their pump status and receive meter readings after every sale in real time.

Salient Features

- Easy installation in any dispenser and tanks

- Supports more than 100 brands of dispensers

- Supports more than 30 brands of ATG systems and probes

- Supports simultaneous operation with 50 dispensers and with 50 tanks

- Built-in web-server for monitoring, configuration, reporting and control

- Communication interfaces: RS-232, RS-485 and Ethernet

- Rich set of interface converters

- Automatic operation with storage of pumps sales and tanks measurements to local database

- Automatic upload of data to remote server

- Full control of dispensers i.e get dispenser status,start, stop , suspend or resume fueling

- Get filling information during dispensing process (volume, amount, price)

- Get transaction information after dispensing process (volume, amount, price)

Our Complete Pump Automation Forecourt controller is linked to our ATG probes (wired and wireless level probes) which are intended for continuous measurement of petroleum products levels (fuel and LPG), produced water level and temperature in tanks at petrol stations, tank farms and refineries. Probes are supplied with length up to 15 m in wired and wireless executions. Also, flexible version of the probes for high tanks is available. This is fully integrated with our Petrol Station management system to allow real time data access